UHMW Polyethylene Applications & Properties

Ultra High Molecular Weight Polyethylene (UHMW-PE)

Known for its outstanding abrasion resistance, high-impact resistance and chemical resistance, Ultra-High Molecular Weight Polyethylene (UHMW-PE) has countless applications across nearly every industry worldwide. UHMW plastic is used to make custom plastic parts including UHMW conveyor parts, UHMW chain guides, mining chute liners, agriculture equipment skid shoes, UHMW fender pads, snowmobile skis snowplow cutting edges and more.

UHMW-PE is a linear polyethylene with an extremely high molecular weight, making it far superior to any other thermoplastic for wear resistance, and by far one of densest polymers available, outperforming even carbon steel for wear applications. No other polymer can match UHMW’s slickness and abrasion resistance.

Industrial Applications for UHMW-PE

Agriculture Applications for UHMW

Our May Wes division pioneered the application of UHMW poly in the ag industry. UHMW is used to make G4 Stalk Stompers to protect combine tires and tracks, skid shoes, auger trough liners, and much more. May Wes products have been featured by the Minnesota Millennial Farmer. See www.maywes.com.

We Are UHMW Experts

Our May Wes Manufacturing Division pioneered the application of UHMW poly in the agricultural industry back in the early 1970s and we have been working with this exceptionally slick and durable polymer ever since. Put our UHMW expertise to work for you for your next plastic compression molding or plastic fabrication project.

Thousands of Custom Plastic Parts Are Manufactured from UHMW

Compression Molded Plastics

Compression Molded Plastics

Compression Molded Plastics

- C&A Pro Snowmobile Skis

- UHMW Belly Pads

- Bridge Pier Protection

- Plastic Bumpers

- Commercial Lawnmower Striping Rollers (overmolded)

- Plastic Dock fenders

- UHMW Filters

- Lead Acid Battery Separators

- Plastic Medical Implants

- UHMW Pinion Gears

- Plastic Pistons

- Poly Capped Bolts

- Poly Outrigger Pads

- UHMW Rollers

- UHMW Screws

- Sliding Plates

- UHMW Star Wheels

- Poly Skid

- C&A Pro Snowmobile Skis

- UHMW Belly Pads

- Bridge Pier Protection

- Plastic Bumpers

- Commercial Lawnmower Striping Rollers (overmolded)

- Plastic Dock fenders

- UHMW Filters

- Lead Acid Battery Separators

- Plastic Medical Implants

- UHMW Pinion Gears

- Plastic Pistons

- Poly Capped Bolts

- Poly Outrigger Pads

- UHMW Rollers

- UHMW Screws

- Sliding Plates

- UHMW Star Wheels

- Poly Skid Shoes

- Plastic Sprockets

- Plastic Valves

- UHMW Wear Pads

- UHMW Plastic Gears

- Plastic Bogey Wheels

- Plastic Corner Guides

- Plastic Idler Sprockets

- Poly Agricultural Parts

- Much More...

Fabricated Plastics

Compression Molded Plastics

Compression Molded Plastics

- Poly Skid Shoes

- 5th Wheel Slickplates

- UHMW Skid Plates

- Spark-Free Cutting Edges

- Poly Trough Liners

- Plastic Washers

- UHMW Wear Strips

- UHMW Sliding Plates

- Plastic Impact Bars

- Plastic Idler Rollers

- Poly Hold Down Bars

- Plastic Guide Shoes

- UHMW Plastic Gears

- Poly Fuel Tank Protectors

- Poly Flanged Rollers

- Snowplow Cutting Edges

- Poly Conveyor Rollers, Guide Rail

- Poly Skid Shoes

- 5th Wheel Slickplates

- UHMW Skid Plates

- Spark-Free Cutting Edges

- Poly Trough Liners

- Plastic Washers

- UHMW Wear Strips

- UHMW Sliding Plates

- Plastic Impact Bars

- Plastic Idler Rollers

- Poly Hold Down Bars

- Plastic Guide Shoes

- UHMW Plastic Gears

- Poly Fuel Tank Protectors

- Poly Flanged Rollers

- Snowplow Cutting Edges

- Poly Conveyor Rollers, Guide Rails and Chain Guides

- UHMW Collars

- Poly Chain Drive Sprockets

- Poly Cable Guides

- UHMW Plastic Bushings

- UHMW Bucket Elevator Guides

- Plastic Boat Bottoms

- UHMW Plastic Bearings

- UHMW Auger Wearshoes

- Poly Auger Liners

- Poly Agricultural Parts

- Much More...

What Can We Make for You?

Compression Molded Plastics

What Can We Make for You?

Do you need custom UHMW plastic parts manufactured ? Please contact us today to discuss your project.

What is the Molecular Weight of UHMW?

UHMW is an Ultra High Molecular Weight Polyethylene with a molecular weight between 3.1 and 11 million, making it one of polymer materials with the highest molecular weight. The high molecular weight contributes to its exceptional properties, such as high strength, impact resistance, and low friction.

UHMW-PE Advantages

UHMW is Impact Resistant

UHMW-PE is incredibly impact resistant. Professional sno-cross racers have been pounding moguls on UHMW C&A Pro snowmobile skis for nearly 30 years.

UHMW Abrasion Resistance

UHMW poly is extremely resistant to abrasion, and holds up better than steel, hardwoods and other polymers in abrasive applications. It’s been used in gritty bulk material handling and agricultural applications for decades. Virgin UHMW has a Relative Abrasion Index of 10 vs 100 for carbon steel and 800 for hard neoprene rubber in Sand Slurry Test Results (Source: Roechling)

UHMW is a Self-Lubricating Low Friction Polymer

UHMW poly is a very slick, self-lubricating non-stick material with a coefficient of friction (dynamic) of 0.12. This allows materials to slide right over it without building up, making UHMW-PE an excellent choice for any application that requires a slippery surface to prevent caking. Oil and grease can be eliminated from bearing applications, making UHMW components a popular choice for commercial food handling and bottling applications.

Non-Porous - Absorbs Virtually No Water/Withstands Many Chemicals

UHMW-PE absorbs virtually no water and withstands many corrosive chemicals – These characteristics make UHMW poly an excellent choice for the food, beverage, pharmaceutical and chemical industries as well as for water treatment applications.

Non-Toxic - Natural Virgin UHMW is Food Safe

Natural virgin UHMW-PE is USDA and FDA approved for direct food contact.

UHMW Poly Withstands Extreme Cold

UHMW-PE is an excellent choice for cold-weather applications. Snowmobilers prefer UHMW snowmobile skis for their durability and slick surface, and cities and contractors often install a UHMW poly cutting edge to snowplows and skid steer buckets to protect paved surfaces from plow damage. UHMW can withstand sub-zero temperatures to -450° (Roechling Polystone® M UHMWPE):

UHMW Withstands High Temperatures

UHMW-PE has a melting point of 320°F (160°C).

UHMW is 8 Times Lighter Than Steel

UHMW-PE is eight times lighter than steel but outwears carbon steel for abrasion resistance by 10 to 1.

UHMW Reduces Maintenance Costs & Downtime

UHMW will save you time and money on maintenance. UHMW-PE reduces corrosion and wear so parts last longer. It also is self-lubricating, eliminating time-consuming lubrication requirements. Slick UHMW-lined chutes are far easier to keep clean than metal.

UHMW Reduces Energy Consumption

UHMW’s slick property helps reduce energy costs by reducing friction and thermal loss. Conveyor belts operate more efficiently because product moves more freely, and farm equipment outfitted with poly passes through fields with less resistance, reducing fuel costs.

UHMW Prolongs Equipment Life & Reduces Maintenance Costs

UHMW poly can be used to protect expensive equipment from wear and tear, and to replace worn metal parts for a fraction of the cost.

Physical Properties of UHMW-PE Plastic

Chemical Resistance of UHMW-PE

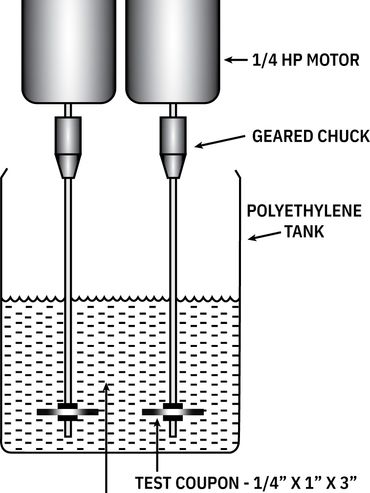

UHMW Sand Slurry Test Results

Sand Slurry Tests and Decades of Industrial Use Prove

UHMW is Extremely Wear Resistant

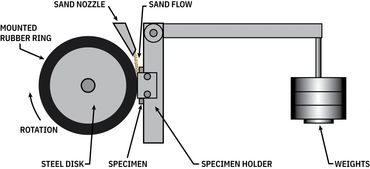

QTM Test for UHMW Wear Called Sand on Wheel

Thermal Expansion of UHMW

Contact Pride Solutions

Pride Solutions

120 Eastgate Drive Southeast, Hutchinson, Minnesota 55350, United States

Hours

Today | By Appointment |

Pride Solutions LLC - Proudly Made in U.S.A.

120 Eastgate Drive Southeast, Hutchinson, Minnesota 55350, United States